New technology to improve safety, quality and productivity on construction sites has been development by Monash University

- Worksites are busy, complex and dynamic environments. Safety, productivity and quality monitoring requires continuous presence of supervisors on site.

- Researchers at Monash University have filed a patent for new technology that can help generate thousands of images of construction machinery, train deep neural networks, and automate monitoring processes.

- For each piece of equipment, this technology can generate thousands of images. By analysing such images using artificial intelligence (AI), on-site safety, quality and productivity can significantly improve.

New, Australian-first technology developed by Monash University engineers will streamline safety, productivity and quality monitoring procedures on building, mining and construction sites.

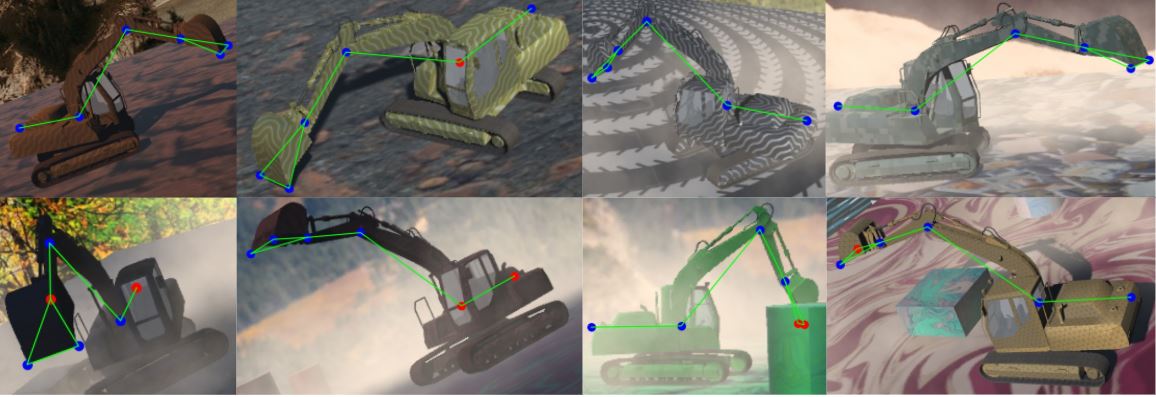

This new technology generates accurate, synthetic images of machinery – such as cranes, scissor lifts, bulldozers and dump trucks – which create large datasets for training deep neural networks to analyse the use of machinery on-site and in a variety of conditions.

It was developed by Dr Mehrdad Arashpour and his team of PhD students and postdoctoral researchers in Monash University’s Department of Civil Engineering.

This new method, which is currently under Australian patent review, removes the need for cameras to be placed on construction machinery, which has time, cost and privacy implications.

The technology can process millions of images of any type of machinery in a short amount of time, and provide detailed information on its key physical and operational features.

In other words, before using an excavator at a building site on a wet day, workers can identify all the safety features of this equipment within a digitised version of the working environment, including rain, clouds, as well as reduced light and visibility.

Over time, this technology could be expanded and used on any and every construction site across the world – from Melbourne to Madrid – depending on the type of machinery in operation.

Dr Arashpour said this application has been designed to improve safety, productivity and quality on building sites and other workplaces.

“Operations involving heavy construction equipment are a critical component of most projects. Heavy construction equipment, vehicles and workers are often required to work closely due to spatial limitations and tight schedules, which often leads to suboptimal performance both in terms of safety and productivity,” Dr Arashpour, Head of Construction Engineering and Management at Monash University, said.

“Preparing large training datasets for specific tasks is currently a manual process, which is highly time-consuming, labour-intensive, error prone, and subject to privacy concerns.

“Our method randomises various critical features of the scene, such as equipment pose and texture, scene texture and lighting, camera location and field of view, and adds other elements to the scene such as simulated dust and occluding objects.”

Presently, safety compliance training procedures involve placing cameras on site to capture images of the machine in operation. From there, the images are labelled manually, including key points of each piece of equipment.

The generated data set is then used to train the artificial intelligence (AI) models and inferences are made regarding classification of different equipment, pose estimation and activity recognition.

The novel Monash-developed method uses game engine technology to generate CAD models of heavy machinery, such as cranes, dump trucks, scissor lifts and other equipment on site, which are then accurately and automatically annotated.

Dr Arashpour and his team have tested several deep neural networks on the real images of the equipment. The results obtained by training deep neural networks using synthetic images are almost always as accurate as real images.

“As compared to traditional data preparation pipelines, the proposed method does not require any manual annotation, which is a labour-intensive and time-consuming process,” he said.

“Furthermore, synthetically generated datasets are advantageous to manually labelled datasets as they can produce pixel-level annotations for the key points of interest. In contrast, manually annotated datasets are susceptible to human error, and monitoring the quality of annotation is also a cumbersome task.

“Our home-grown technology has the potential to modernise the building and construction industry across the world, and improve safety, quality and productivity.”

Source: Medianet Press Release 7 June 2021